The impact of shipping containerization was truly revolutionary for the world and its economy. In the latter half of the last century it caused explosive growth in global exports and imports. Despite shipping containerization being one of the greatest innovations in modern history, what it is, how it started, when it came to be, and what its impact was, is not well-known.

How shipping containerization revolutionized the world

How shipping containerization revolutionized the world

What is shipping containerization?

Shipping containerization is a strict international dimensions standard that allows shipping containers to be easily transported, as a whole, over sea, and by rail and truck. These shipping containers are called ‘intermodal’ or ‘ISO’ containers. They have standardized lengths, widths, heights and strengths, and are individually numbered. This permits them to be:

- Tracked using computerized systems

- Easily loaded, unloaded and stacked

- Transferred from one mode of transport to another

- Transported efficiently over long distances

Intermodal handling and transport

The handling systems used for shipping containerization are fully mechanized using standardized cranes and forklift trucks. This allows for shipping containers to be easily loaded, transported and unloaded, without being opened, on transport modes such as:

- Cargo ships

- Container ships

- Rail flat cars

- Semi-trailer trucks

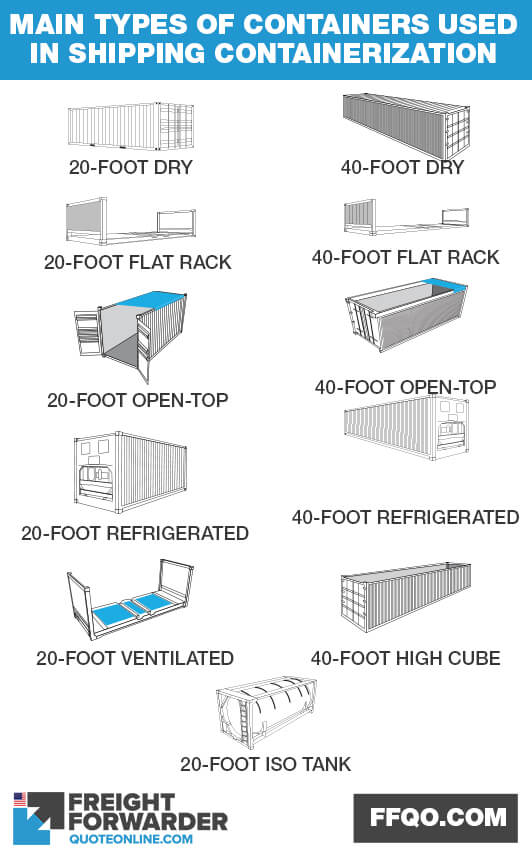

Main types of shipping containers

In the shipping containerization system, 11 main types of containers, comprising a set, are used. These make for easy global exporting and importing of goods such as bulk grains, raw materials, manufactured products and perishables. The main container types are:

- 20-foot and 40-foot dry

- 20-foot and 40-foot flat rack

- 20-foot and 40-foot open-top

- 20-foot and 40-foot refrigerated

- 40-foot high cube

- 20-foot ventilated

- 20-foot ISO tank

Main types of containers used in shipping containerization

Main types of containers used in shipping containerization

How did shipping containerization come about?

The concept of shipping containerization first came about several centuries ago. In England, boxes similar to shipping containers were used to combine railway and horse-drawn transport as far back as 1792. The concept, however, remained poorly developed until after World War II. The post-war boom in global trade drove the development of shipping containerization, and it became obvious that a system such as this would dramatically reduce the costs and transit times of freight around the world.

Who invented shipping containerization?

Shipping containerization was invented in 1956 by Malcom McLean, a US trucking entrepreneur. McLean had purchased a steamship transport company so he could ship complete truck trailers with their goods still inside, thus combining the two freight modes. He realized a better way of combining freight modes would be to use one standard type of shipping container that could be unloaded from a truck and loaded directly onto a ship

His major achievement, however, was yet to come. He saw that freight efficiency would be greatly improved by utilizing the same shipping container, with the goods inside, across all major transport modes. Shipping containers moving seamlessly between trucks, ships and trains would ensure minimum disruption to cargo during transport from origin to destination. This simplified the global logistics process overall and revolutionized international trade.

International standardization

In 1961, the International Organization for Standardization created the ISO technical committee ISO/TC 104. This standardized virtually every aspect of the shipping containers used in containerization. The system quickly became widely adopted and made the global supply chain much smoother. The ISO standard allowed for the efficient facilitation of global logistics.

Take this example where cargo is shipped from China to the USA:

- Consumer goods packed into containers in China

- Directly loaded and carried by cargo ship

- Unloaded directly onto trains and trucks in USA

- Transported to warehouses anywhere in the country

Over time, the technology for shipping containers expanded beyond dry closed boxes to include refrigeration and tanks. This allowed perishables and fluids to be shipped anywhere around the world.

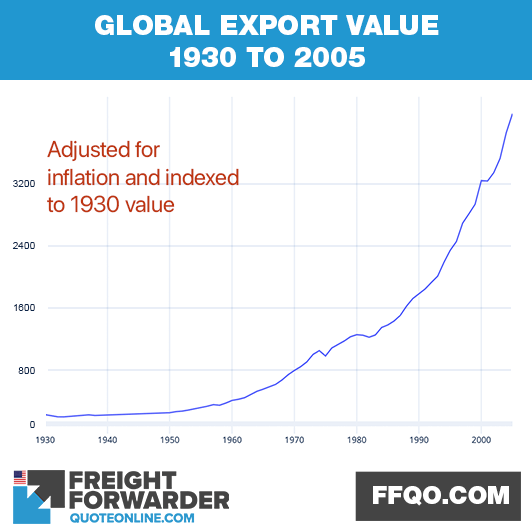

Impacts of shipping containerization

Shipping containerization brought major reductions in transit time, handling labor and costs, decreasing congestion in ports due to shorter shipping times. Containerization removed the need for manual sorting and warehousing of cargo at the ports. It eliminated vast numbers of dock worker jobs that were required for the loading and unloading of ships. As the shipping containers were not required to be opened, it greatly reduced losses from damage and theft.

Global export value 1930 to 2005

Global export value 1930 to 2005

Reductions in shipping time

Prior to shipping containerization, loading and unloading was labor-intensive and time-consuming. Cargo ships would be expected to be in ports for a couple of weeks. Freight was not a single process, but a series of distinct modes (trucks, trains and ships). When the mode changed, manual labor was required to transfer each piece of cargo. Shipping containerization greatly reduced shipping time by making the changes in mode seamless. The massive cargo ships traveling the seas today can be in and out of a major sea port within 10 hours. This increase in speed is particularly beneficial for perishable goods.

Elimination of breaking bulk and warehousing

Before shipping containerization, loading and unloading cargo was known as ‘break bulk cargo’. Each item was manually loaded and packed on and off cargo ships. This break bulk labor requirement was intensive, requiring ships to have long stays in ports. As the break bulking was a slow process, cargo had to be held in warehouses while it was being loaded and unloaded.

Vast jobs losses

Shipping containerization removed vast numbers of dock workers and many associated jobs. Liverpool was a typical major sea port, and its population decreased by nearly 20% over four decades.

Closure of inland ports

The change to the new cargo and container ships resulted in the closure of many inland ports. London, Manchester and Gloucester were great inland port cities, however the new ships could not navigate their shallow rivers so they were unable to benefit from the system.

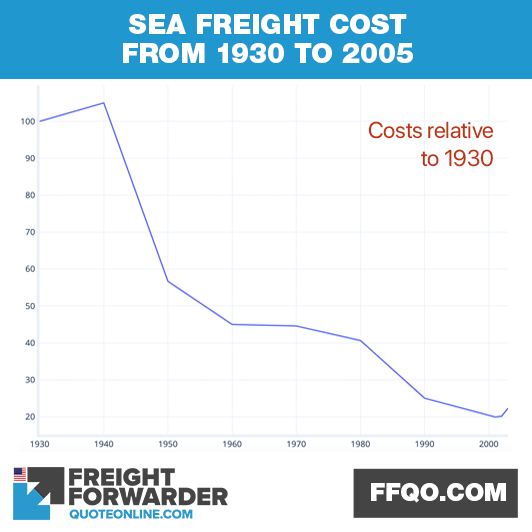

Cheaper freight

The ‘breaking bulk’ cost was up to 50% of the total cost of shipping prior to shipping containerization. With the manual handling and warehousing of cargo eliminated, theft and damage was significantly reduced. This decrease in cargo losses reduced the premiums on marine insurance.

When containerization started in the early 1960s, the cost of sea freight had already dropped by 55% compared to what it cost in 1930. By the 1990s, the cost had halved again and dropped to 25% compared to 1930. This drop would have occurred in the 1960s to 1980s, but there was a 950% increase in oil price over this period, and this nullified the savings made from containerization over that time.

Sea freight cost from 1930 to 2005

Sea freight cost from 1930 to 2005

Looking for help on international freight for the USA?

Putting together a great feature on shipping containerization shows how passionate we are about international freight. For your international freight importing and exporting, if you want to work with a reputable and innovative freight forwarder then consider us. We are an international freight specialist that gives complete and transparent costings – nothing hidden.

Our international freight network from the USA has more than 40,000 locations around the world. We run a transparent and efficient international freight service, so contact us online and send a message. You can even message us on Facebook for a quote on doing your international freight to and from the USA.