A refrigerated container (reefer) is a specialized container that can control temperatures. They can keep goods frozen at temperatures going as low as -76 degrees F. This allows perishable items to travel across the world. This includes:

- Meat

- Fruit

- Seafoods

- Vegetables

- Dairy products

- Chemicals

- Pharmaceuticals

Goods requiring the use of a reefer (refrigerated container) when shipping

How does a refrigerated container work?

The secret behind refrigerated containers rests on its parts namely:

The compressor

This part of the reefer draws gaseous refrigerant and compresses it. This process creates pressure which liquefies the gas. As a result, it gives off heat to the body of the compressor and its surrounding air.

The condenser

The condenser works like a radiator. The heat from the liquid flows to the walls of the tubing. It then goes towards the attached fins at the outside. With more surface area, these fins cool the outside air drawn through the condenser fan.

The evaporator

Since the refrigerant has transferred most of the heat to the condenser and it has managed to transform this into cool liquid, the refrigerant is then released through the evaporator. This is done via the metering valve which works like a throttle to control the amount of cooling.

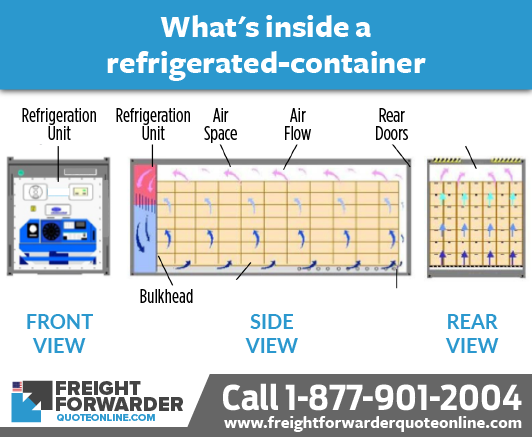

Inside a reefer (refrigerated container)

Inside a reefer (refrigerated container)

Parts of a reefer (refrigerated container)

Refrigerated container case scenarios

The following are some of the case scenarios related to refrigerated containers:

Chilled cargo

Chilled cargo requires cartons to have ventilation. This is needed for air to flow through the cargo and for the gases and heat to be expelled.

Air flow within a chilled cargo container

Air flow within a chilled cargo container

Frozen cargo

Frozen cargo has to be “block stowed” (stowed together). No gaps should exist between the cargo and the walls to ensure airflow moves smoothly inside the cargo as shown in the image below.

Air flow within a frozen cargo container

Air flow within a frozen cargo container

Cold Treatment

Some fruits may carry potential pathogens so certain countries require cold treatment of these fruits. Some of these countries include:

- China

- Japan

- Nigeria

Fruits will have to be pre-cooled to a lower temperature than that of the commercial market. Steri probes are inserted into its pulp, which could be an average of three per shipment. This is placed inside the refrigerated container to ensure the pathogen level of the goods can be properly monitored.

Checklist for stowage of reefer cargo

These are some of the do’s and do not’s when stowing reefer cargoes:

Reminders when stowing a refrigerated container cargo

- Avoid stuffing the cargo beyond the end of the T-floor or above the red load line

- If possible, have the cargo tightly wedged. This ensures it will not shift during passage.

- The temperature should be set based on the goods to be loaded

- Always check the de-humidification controls

- For cargo with pre-cooling requirement, it is the cargo that is to be pre-cooled and not the reefer. This is unless the container is to be loaded in an airlocked cold tunnel in the cold storage

- Set the ventilation at the correct level

- Air flow should follow the path with the least resistance. Close the doors, may it be cardboard or wood. Avoid gaps between the pallets to eliminate any restrictions to the air flow

What to consider in choosing a refrigerated container carrier?

Save money. Learn tips on how you can choose the best reefer carrier for your needs:

Geography

Identify where your goods will go. Consider the timing of your cargo transport and the manner how these refrigerated containers will be moved. Bear in mind that Full Truck Loads (FTL) and Less than Truck Loads (LTL) can be fragmented in the US. This is not yet considering the seasonal and ambient temperature of these locations.

Check the required temperature

Reefers need to maintain a temperature between 55 degrees F to -20 degrees F. However, some refrigerated containers are flexible enough to move goods within a wide spectrum of temperatures.

You need to check if they can comply to your temperature requirement. Otherwise, your goods may end damaged upon arrival to its destination.

Loading capability

As mentioned earlier, proper airflow is absolutely needed to maintain the air temperature inside the container. See how your goods will be loaded to determine how much cargo can fit in the reefer. This is most important in optimizing your supply chain as it helps you allocated FTL and LTL shipments based on space.

Monitoring capability

Certain carriers offer remote monitoring of their carrier. This allows you to see if the reefer remains providing the 25 degrees temperature you have requested any time of the day, even while it is travelling. This gives you better view of how your items will be transported.

Efficient communication

It’s not enough that the carrier can move your goods on the right temperature at the right time and place. They should also efficiently communicate when these goods have arrived. This includes identifying who is responsible for any carrier negligence, such as “out of temperature” problems.

Shipping your goods using a refrigerated container (reefer) is not simple. It is even more complicated if you end up choosing a freight forwarder who is inexperienced in handling these types of cargo.

Choose a freight forwarding company who can deliver your needs without compromising the quality of your products. Talk to Freight Forwarding Quote Online (FFQO) regarding your request. Send us a message.